Challenge

Machine repairs are done on a error demand basis: If and issue occurs, a technician will be dispatch to address and solve the issue, stopping the entire production line if needed. Additionally, chemical composition of materials baths are being manually checked to ensure PH and acidity levels. The goal is to reduce maintenance windows running then before issues happen and in a less demand time of the day and receive alerts when chemical composition are changing above or below pre-defined thresholds.

Approach

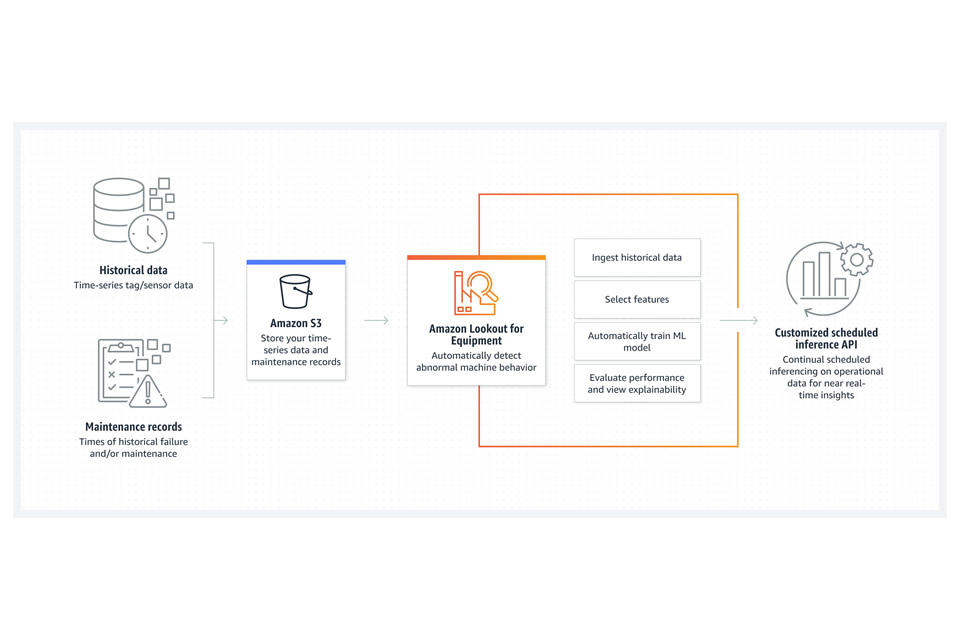

Using pre-build AI models of Amazon Lookout for Equipement plus custom built specific for customer, we have:

- Built a Data Lake for data storage (historical and current)

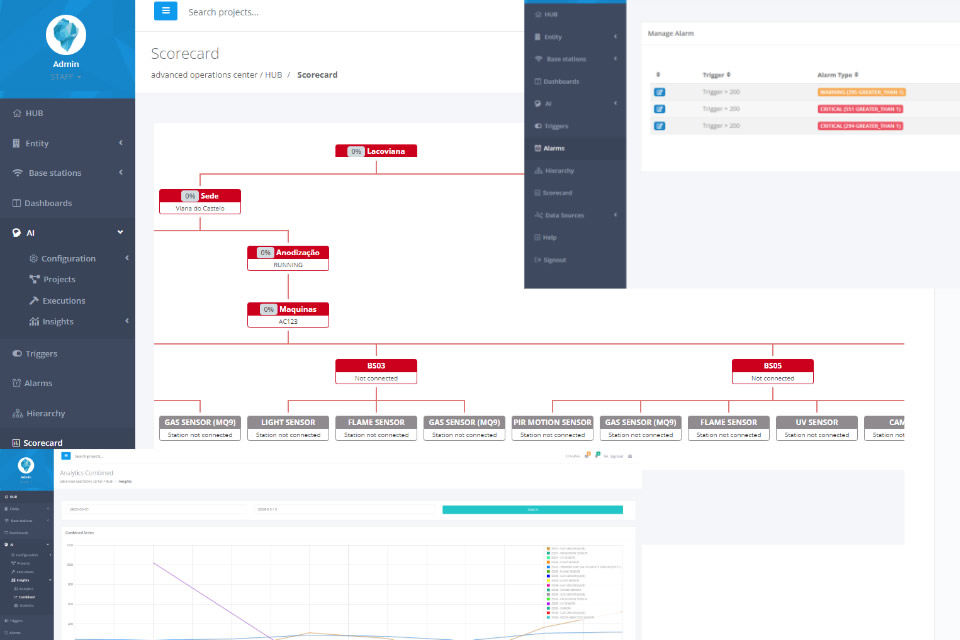

- Develop a web application to analyse data and tag/identify events

- Develop a trigger mechanism to send alerts when:

- Specific threshold are above/below pre-defined limits

- Advance notices for potential errors/needed repairs

- Visual analytics like Balance Scorecard of entire company/production lines

Value Delivered

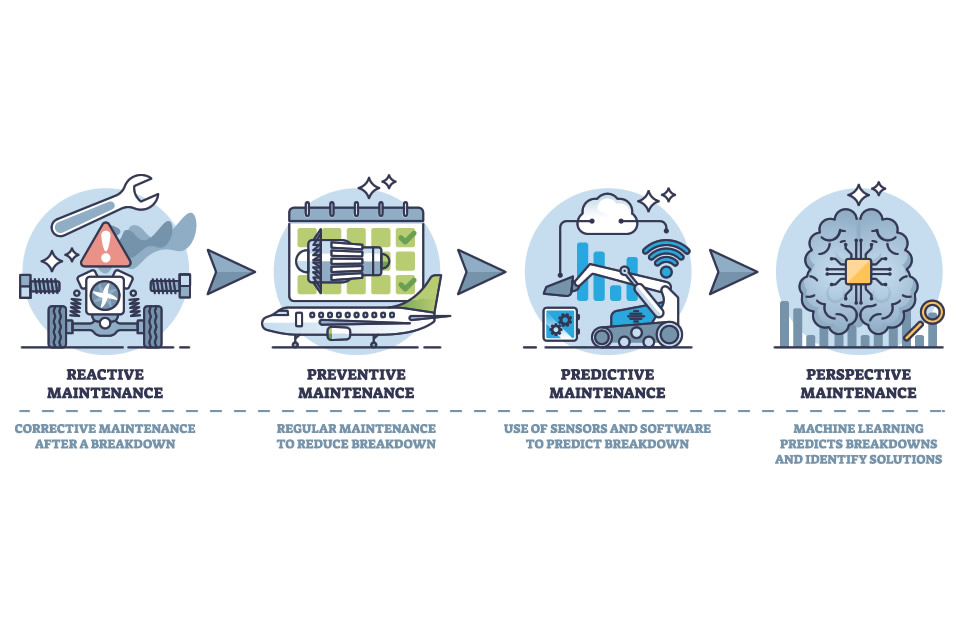

Benefits of a predictive maintenance platform using AWS, supported by a Data Lake and leveraging machine learning and analytics:

- Proactive Maintenance Scheduling: Predict failures before they occur to minimize equipment downtime.

- Strategic Asset Management: Use trend analysis for better decision-making about asset utilization and lifecycle management.

- Reduced Operational Risks: Implement preventive strategies to mitigate risks associated with equipment failure.

- Automated Real-Time Reporting: Generate automated reports and dashboards for up-to-date maintenance insights.

- Enhanced Historical Analysis: Leverage historical data to improve predictive accuracy and strategic planning.

- Early Anomaly Detection: Identify and address unusual machine behavior before it leads to breakdowns.

- Immediate Predictive Alerts: Receive alerts for potential issues to prevent costly downtimes.

- Cost Efficiency: Reduce maintenance costs by avoiding unnecessary repairs and optimizing part usage.

- Increased Operational Efficiency: Improve overall operational productivity through efficient equipment management and reduced downtime.

Cloud Experts

Guidance and hands-on-keyboard through your cloud journey, from migration to AI in production

Head Office

Rua Ramalho Ortigão 213

4900-422 Viana do Castelo

Portugal

Phone: +351 258 121 902 (Call to national fixed network)

Mobile: +351 964 367 684 (Call to national mobile network)

Email: account@valuedate.pt